The role of robotic vision enables instant decision-making

The Significance of an Optical Fibre Diameter Analyser in Keeping Sector Specifications

The relevance of an Optical Fibre Diameter Analyser can not be overemphasized in the context of market requirements. This modern technology guarantees precise dimensions, which are essential for excellent signal transmission and decreased depletion. By finding incongruities early, makers can maintain stringent quality control measures. Nevertheless, the effects of these measurements extend past conformity. Discovering the wider effect on system efficiency exposes complexities that warrant additional exploration.

Understanding Optical Fibre Diameter Analysis

Optical fibre diameter evaluation plays a necessary function in ensuring the performance and reliability of fibre optic systems. Exact dimension of fibre diameter is crucial, as it directly affects signal transmission effectiveness and total system stability. Variants in diameter can cause enhanced attenuation, reduced transmission capacity, and higher sensitivity to environmental variables.

By employing specific dimension strategies, makers can maintain rigid quality assurance, making sure that fibres satisfy industry standards. This evaluation additionally promotes the recognition of issues or incongruities throughout production, permitting timely rehabilitative activities.

Additionally, understanding the diameter criteria aids in the choice of appropriate ports and fittings, therefore improving compatibility within the network. In general, detailed optical fibre diameter evaluation is a foundational element of fibre optic innovation, underpinning developments in telecoms, data transmission, and numerous applications across various industries.

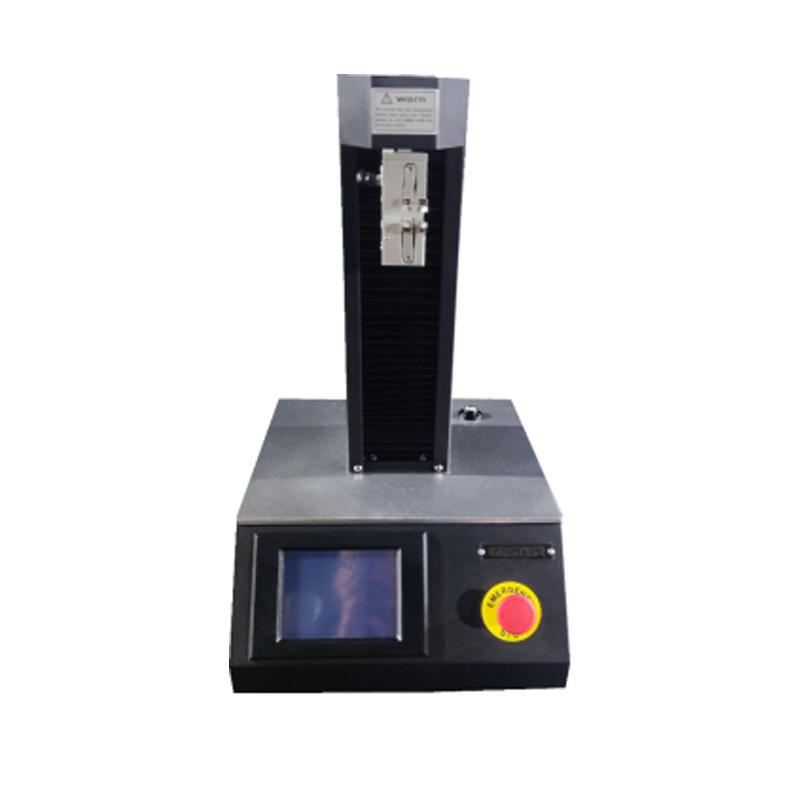

Secret Functions of Optical Fibre Diameter Analysers

Optical fibre diameter analysers are outfitted with several essential functions that improve their performance. Significant amongst these are accuracy dimension abilities, which ensure precise readings, and real-time monitoring features that offer instant feedback during the analysis process. Additionally, an user-friendly interface layout promotes simple procedure, making these devices accessible to a wider variety of customers.

Accuracy Dimension Capabilities

When it pertains to ensuring premium fibre production, precision measurement abilities are critical in diameter analysers. These devices utilize innovative modern technologies to provide accurate dimensions of fibre diameter, permitting makers to keep rigorous tolerances. High-resolution optics and sophisticated formulas allow the detection of min variants in diameter, vital for producing trusted and regular optical fibres. Additionally, the ability to gauge across a vast array of diameters boosts adaptability, accommodating numerous production demands. The combination of calibration standards ensures that dimensions remain exact over time, lowering the danger of issues. By utilizing these accuracy measurement capacities, makers can support sector standards, boost product high quality, and inevitably drive client satisfaction in the affordable fibre optics market.

Real-Time Surveillance Features

Real-time surveillance features are crucial for improving the performance and effectiveness of fibre production procedures. These capacities enable constant analysis of optical fibre diameter throughout manufacturing, making sure that any kind of variances from defined standards are promptly detected. By offering immediate responses, manufacturers can quickly change criteria, reducing waste and maintaining top quality control. In addition, real-time surveillance assists in the recognition of patterns and patterns in manufacturing information, supplying beneficial understandings for procedure optimization. The assimilation of these attributes into optical fibre diameter analysers supports aggressive decision-making, empowering operators to react swiftly to possible problems. As a result, the application of real-time monitoring not only supports sector requirements yet also improves general efficiency and product dependability.

User-Friendly User Interface Design

A well-designed interface is necessary for the reliable procedure of optical fibre diameter analysers. Such user interfaces prioritize simplicity and access, permitting customers to browse the system effortlessly. Key functions commonly include instinctive menus, clear graphical depictions of data, and customizable settings to accommodate different user preferences. Real-time responses devices improve the user experience by supplying immediate understandings right into dimensions. Additionally, reliable error messaging guides users in repairing issues swiftly, decreasing downtime. The consolidation of touchscreens and responsive layouts additionally promotes interaction, making it much easier for service technicians to run the analyser in varied environments. Ultimately, a straightforward interface not just boosts effectiveness yet also enhances the total precision of the measurements, adding to market requirements in optical fibre manufacturing.

The Role of Diameter Dimension in Quality Assurance

Although diameter dimension might look like a small detail in the manufacturing of optical fibres, it plays a significant role in making certain overall quality assurance. Consistency in diameter is essential for preserving the optical performance and structural stability of the fibres. Variants in diameter can result in issues such as signal loss, increased depletion, and decreased tensile toughness, eventually jeopardizing the integrity of the fibre in various applications.

Quality control procedures integrate specific diameter measurement to identify issues early in production. By applying an optical fibre diameter analyser, suppliers can determine any type of variances from defined resistances, facilitating instant rehabilitative activities. This proactive approach not just enhances product top quality yet additionally minimizes waste and lowers manufacturing prices.

Compliance With Market Standards and Laws

Compliance with industry requirements and guidelines is crucial for the precise procedure of an optical fibre diameter analyser. Complying with these standards guarantees that manufacturers preserve quality assurance throughout the production process. Satisfying governing needs not only improves item dependability yet also fosters consumer count on.

Making Certain Quality Assurance

Ensuring adherence to market standards is important for preserving the stability and efficiency of optical fibre items. Quality assurance plays a pivotal role in this process, as it entails the methodical monitoring of fibre diameter to guarantee consistency and reliability. An optical fibre diameter analyser is a vital device in accomplishing these high quality standards, supplying specific measurements that aid recognize inconsistencies from developed requirements. By using this modern technology, makers can promptly identify and attend to any abnormalities, making certain that products fulfill the required efficiency standards. Routine evaluation via such analysers not only supports item top quality fibre testing equipment however likewise enhances client trust fund and satisfaction. Inevitably, robust quality control measures cultivate an affordable edge in the optical fibre sector, advertising long-lasting success and compliance with criteria.

Satisfying Regulative Demands

As suppliers navigate the intricacies of the optical fibre market, conference regulatory demands becomes vital for assuring product safety and security and performance. Conformity with industry requirements not just reduces possible risks however additionally enhances customer self-confidence in the products provided. An optical fibre diameter analyser plays a crucial duty in this process, enabling makers to verify that their products follow defined dimensions and tolerances. By utilizing such analyzers, firms can guarantee that their optical fibres satisfy the rigorous policies stated by industry authorities. This aggressive technique to top quality assurance not only helps with conformity yet also enhances the production procedure, reducing the chance of expensive recalls or denials. Inevitably, adherence to regulatory standards is essential for maintaining an one-upmanship on the market.

Benefits of Accurate Diameter Measurement

Accurate diameter dimension plays a necessary role in the performance and reliability of optical fibers. Guaranteeing that fibres fulfill specified diameter resistances minimizes signal loss and optimizes transmission effectiveness, straight impacting overall system performance. This precision is vital in preserving optimal light proliferation, as even minor variances can cause boosted attenuation and diminished optical signal high quality.

In addition, precise dimensions boost compatibility in between parts in fibre optic systems, assisting in smooth assimilation and lowering the threat of failures. Constant diameter measurements also add to boosted manufacturing processes by recognizing prospective flaws early, subsequently reducing waste and reducing production costs.

Integrating Optical Fibre Diameter Analysers Into Manufacturing

Integrating optical fibre diameter analysers into production procedures enhances the capacity to preserve stringent high quality control measures. By using these analysers, producers can achieve precise and consistent dimensions of fibre sizes, which is necessary for making sure product performance and dependability. The combination process commonly entails placing analysers at bottom lines along the assembly line, making it possible for real-time tracking and immediate feedback on diameter variations.

This aggressive technique enables for quick changes to the production criteria, minimizing the danger of problems and waste. Additionally, the data gathered can be used for analytical procedure control, adding to continuous enhancement efforts. Operators are equipped with actionable insights that promote notified decision-making relating to product use and manufacturing techniques. Eventually, the consolidation of optical fibre diameter analysers not just boosts product top quality yet likewise supports conformity with market standards, enhancing a business's reputation for quality in the competitive optical fibre market.

Future Fads in Optical Fibre Dimension Innovation

Arising improvements in optical fibre measurement modern technology are positioned to change the industry. The consolidation of expert system and machine discovering is expected to improve accuracy and effectiveness in diameter analysis. These technologies make it possible for real-time information handling, enabling for prompt changes throughout production, therefore reducing waste. Additionally, the advancement of non-contact dimension techniques assures a reduction in physical interaction with fibres, protecting their stability.

Additionally, miniaturization of measurement gadgets is expected to cause more mobile and easy to use solutions, helping with on-site assessments. optical measurement system. Integration with IoT systems will certainly make it possible for remote tracking and information collection, promoting boosted anticipating upkeep and quality assurance

As markets increasingly require higher efficiency requirements, the evolution of optical fibre dimension tools will certainly play a critical function in meeting these expectations, making certain that makers can constantly deliver high-grade products while adhering to rigid governing requirements.

Regularly Asked Questions

Exactly How Typically Should Optical Fibre Diameter Measurements Be Performed?

Regularity of optical fibre diameter measurements commonly relies on manufacturing quantity and high quality needs. Regular checks, frequently everyday or weekly, aid ensure constant quality and adherence to requirements, minimizing prospective issues in fibre production procedures.

What Are the Regular Prices of Optical Fibre Diameter Analysers?

The common prices of optical fibre diameter analysers differ widely, varying from numerous thousand to tens of countless bucks, depending upon attributes, precision, and maker, affecting choices for services purchasing quality dimension innovation.

Can Diameter Analysers Be Calibrated On-Site?

Diameter analysers can often be adjusted on-site, enabling immediate adjustments to ensure precision. The particular procedures and demands may vary depending on the manufacturer's standards and the innovation made use of in the analyser.

What Types of Fibres Can Be Calculated With These Analysers?

Optical fibre diameter analysers can measure numerous fibre types, including single-mode, multi-mode, specialized, and large-core fibers. Each kind requires particular calibration setups to guarantee exact and reputable diameter dimensions throughout the manufacturing process.

Are There Specific Upkeep Needs for Diameter Analysers?

Diameter analysers require normal calibration to ensure precision, along with routine cleaning to prevent debris accumulation. Furthermore, checking software application updates and examining mechanical components contribute to their perfect efficiency and durability in determining fibre sizes efficiently.